Thermal Transport and Fracture Behavior of Sintered Fuel Pellets: Experimental Validation of NEAMS Tool MARMOT

Objective: validate fuel behavior models developed in MARMOT

This project will perform extensive thermal transport and fracture experiments on UO2 to improve understanding of the impact of microstructure on thermo-mechanical properties. Experiments include:

- Sintering UO2 samples with well-controlled microstructures

- Thermal conductivity measurements of well-characterized UO2 samples

- Indentation testing of sintered UO2 with various grain size, porosity, and stoichiometry to obtain fracture and crack propagation mechanisms

- Validation and uncertainty quantification of the MARMOT thermal transport and fracture models

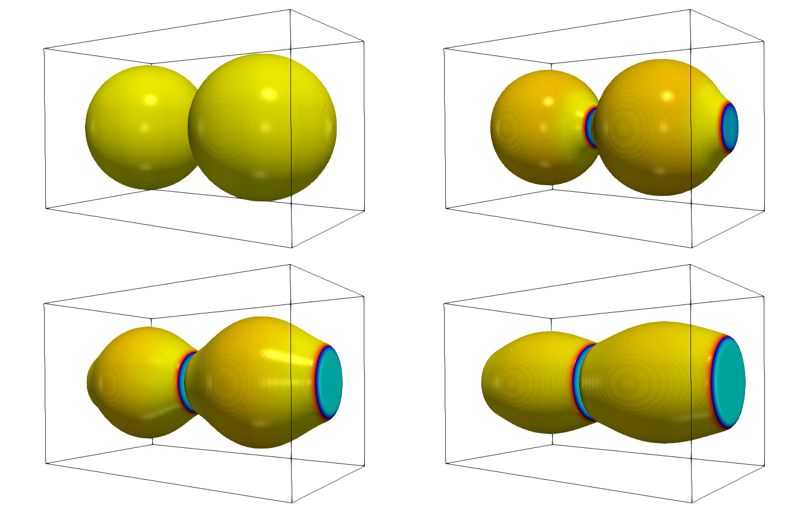

Sintering and Irradiation-Enhanced Densification Modeling of UO2 Fuel Pellets

Objective: develop a phase-field model to describe the mesoscale behavior of UO2 fuel pellets during manufacturing and reactor operation

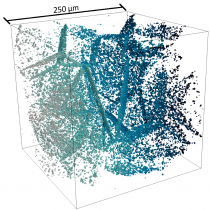

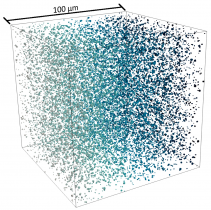

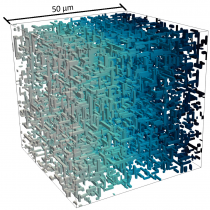

UO2 fuel pellets are manufactured through sintering, which places a powder under heat and pressure until the particles coalesce into a porous mass. The sintering process can be varied to give a wide variety of microstructural, thermal, and mechanical properties. These properties have a large impact on fuel behavior and performance during reactor operation. Sintering continues in the reactor as pores continue to close under the heat and pressure of the reactor environment. However, irradiation speeds up the thermodynamic processes which cause sintering, making predicting this behavior that much more difficult to model. This project will:

- Improve existing phase-field sintering models to more accurately capture the physical mechanisms which cause sintering

- Develop the tools necessary to perform large-scale simulation of phase-field sintering

- Combine sintering physics with irradiation damage models to develop a phase field irradiation-enhanced densification model

- Model fuel sintering and densification over the entire life-cycle of the pellets

- Funding provided by the Nuclear Energy Advanced Modeling and Simulation (NEAMS) program through the Idaho National Laboratory Fuel Modeling and Simulation department

Radiation-induced swelling and microcracking in SiC cladding for LWRs

Objective: develop a master phase-field equation that can predict the amount of swelling and micro cracking in SiC cladding material as a function of temperature and irradiation histories

After the 2011 Fukushima accident, SiC gained attention as a potentially less hazardous cladding material for use in nuclear fuel rods. However, our understanding of irradiation-induced swelling is incomplete. Current models of irradiation-induced swelling in SiC have been largely empirical, so they cannot be used to predict the microstructural dependence of microcracking. Objectives of this project include:

- Understanding defects that form within the range of temperatures relevant to fuel cladding

- Develop a governing set of equations for SiC behavior in these ranges

- Model SiC behavior in operation and accident scenarios

Development of Accident Tolerant Fuel Options For Near Term Applications

Objective: develop computational tools to evaluate accident tolerant fuel (ATF) options in order to increase accident tolerance

Since the 2011 Fukushima accident, dozens of new accident-tolerant fuels have been proposed for use in Light Water Reactors. Each new concept involves some changes to the conventional UO2 pellets and Zircaloy cladding. Testing each of these fuel concepts would be prohibitively expensive. In order to get a better idea of which concepts are worth exploring further, computer simulations will be used to estimate fuel behaviors. This project will:

- Develop computer models of several accident-tolerant fuel concepts

- Evaluate models under transient and steady conditions

- Estimate melting time for fuel and core components

- Gather experimental data to validate and improve models

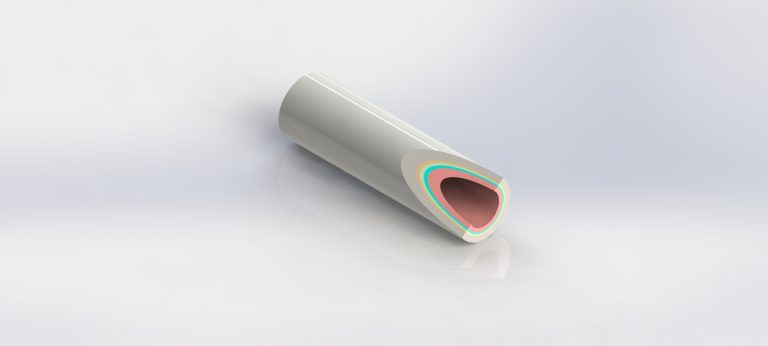

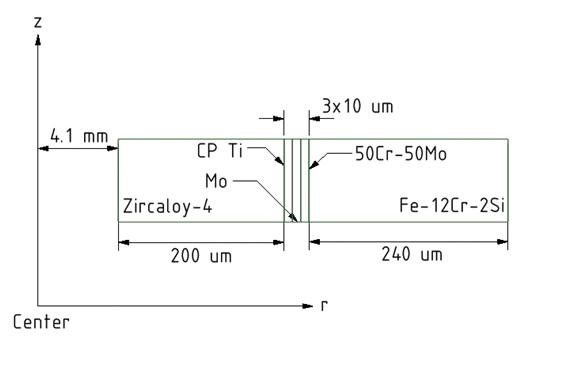

Multilayer Composite Fuel Cladding for LWR Performance Enhancement and Severe Accident Tolerance

Objective: develop new cladding material for LWR, that can enhance LWR performance and increase the safety margin during loos of coolant accident

Funded by: Nuclear Energy University Program (NEUP), US Department of Energy

One of the major goals of the Accident Tolerant Fuel (ATF) programs is to develop new fuel cladding materials that can withstand higher oxidation under the loss of coolant accident. This research project aims at analyzing and evaluating one of the newest concepts for a cladding material: a multi-metallic layered composite (MMLC). The goal of this study is to use multiscale modeling and simulation to assist in the evaluation of the MMLC concept as an ATF cladding material. The work will focus on three potential problem areas: thermal stresses that may develop within the cladding due to thermal expansion mismatch, the formation of problematic interfacial phases that could form due to interdiffusion, and stresses that may result from irradiation-induced shape change that may occur in the various layers. The research is expected to anticipate the mechanical and thermal behavior of the composite cladding including the interfacial phases under the normal operating condition and during severe accident scenarios. These predictions could be imperative in designing and optimizing the MMLC concept, which could reduce the cost of nuclear power generation by enhancing performance and increasing the safety margin.

- Develop computer models of cladding performance

- Analyze LWR cladding in terms of mechanical performance and phase stability

- Characterize and model joining techniques

- Validate models with experimental data

Surface Manufacturing for Specific Wetting Behavior

Objective: better understand the mesoscale material properties that create hydrophobic and hydrophilic surfaces

Mesoscale surface structures have been developed in recent years which dramatically affect how the surfaces interact with water. However, the cause of this change is largely unknown. This project seeks to:

- Understand the material properties that affect this behavior

- Develop phase-field based computer models of this interaction

- Design new surfaces to improve interactions with water even further

A Coupled Experimental and Simulation Approach to Investigate the Impact of Grain Growth, Amorphization, and Grain Subdivision in Accident Tolerant U3Si2 Light Water Reactor Fuel

Objective: the objectives of this project are to determine temperature and dose thresholds for the occurrence of grain growth, amorphization, and grain subdivisionin U3Si2 fuel using experiments and simulation

U3Si2 is a candidate for an accident tolerant fuel system for existing light water reactors. However, before this fuel can be adopted, we need to learn more about the microstructure evolution that takes place during reactor operation. In this project, we are specifically investigating various changes to the grain structure. This information will be provided to the Fuel Cycle R&D program, as well as to other interested vendors, to assist in the development of U3Si2 as an accident tolerant fuel concept.

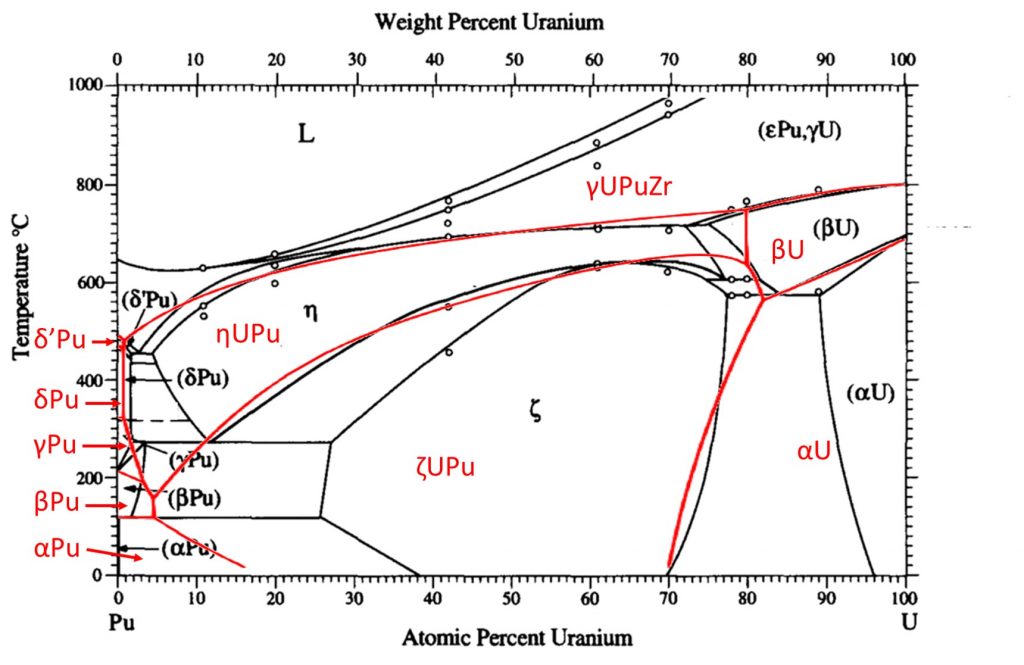

Development of a Phase-Field Model for Constituent Redistribution in Uranium-Plutonium-Zirconium

Objective: develop a phase-field model for uranium-plutonium-zirconium (U-Pu-Zr) and use it to study constituent redistribution and explore the use of coupled experimental and mesoscale simulation techniques

Use of minor actinide transmutation fuels, of which U-Pu-Zr is the most promising candidate, can mitigate the burden associated with long term waste stewardship. Unfortunately, the complex constituent redistribution and phase change behaviors exhibited by U-Pu-Zr impede alloy selection and fuel qualification. Use of a systematic approach based on coupling experimental and mesoscale simulation techniques will help us to overcome these challenges. This approach will allow us to make mechanistic, quantitative predictions about the property evolution and performance of U-Pu-Zr fuels, expediting alloy selection and fuel qualification. To this end, a phase-field model for U-Pu-Zr will be developed and used to identify:

- the constituent redistribution and phase change behaviors expected in U-Pu-Zr fuels under normal operating conditions

- how these behaviors are influenced by thermodynamic, kinetic, and mechanical considerations

- the thermodynamic, kinetic, and mechanical properties that most influence these behaviors

- best practices for coupling experimental and mesoscale simulation techniques

- In collaboration with Assel Aitkaliyeva and Cynthia Adkins

- Funding provided by INL LDRD

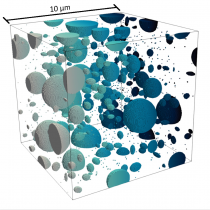

Mesoscale Simulation of Modified UO2 Fuel Performance

Objective: to predict the thermal conductivity and fission gas release for UO2 fuels with BeO and SiC additives using meso-scale simulations

UO2 nuclear fuels have an extremely low thermal conductivity which creates large thermal gradients within nuclear fuel pellets during operation. These thermal gradients cause thermal fracturing, degrading the fuel and creating channels that assist fission gas release and shorten the fuel’s expected lifetime. The incorporation of high thermal conductivity additives to the nuclear fuels should allow heat to more readily dissipate throughout the fuel pellet, thus reducing the negative impacts associated with the large thermal gradients. We hope to answer the following questions with our research:

- do high thermal conductivity additives reduce thermal gradients in UO2 fuels

- how does the microstructure of the additive affect fuel performance

- how does the presence of additives impact fission gas release