Current Research

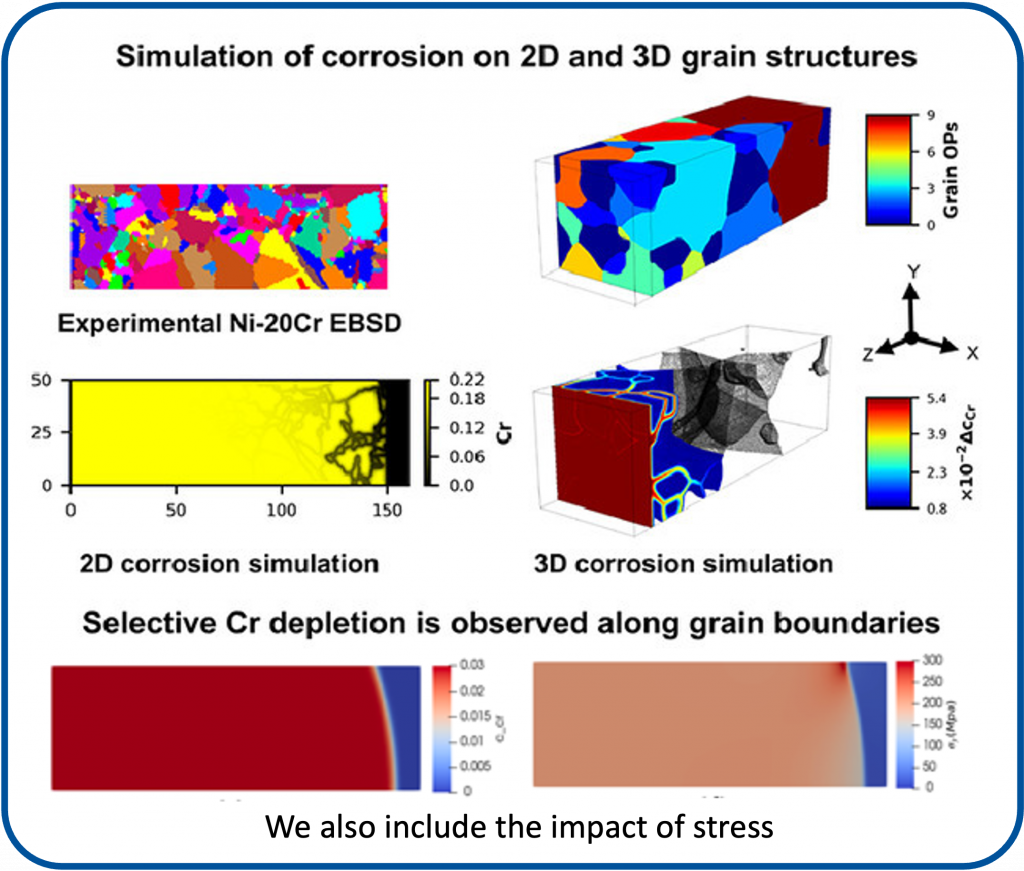

Developing Mesoscale Model of Structural Alloy Corrosion by Molten Salt

We are developing a mesoscale model of the corrosion of structural alloys, including Ni-Cr alloys and stainless steels, by molten salt. The electrochemical model includes the impact of the alloy free energy and salt chemistry. We are actively adding the impact of stress and radiation on the corrosion behavior. We are also adding the impact of water vapor.

Researchers: Thompson Igunma, Soumya Bandyopadhyay, Chaitanya Bhave

Collaborators: INL, University of Wisconsin-Madison

Funding: NEUP, DOE NEAMS

Papers:

An electrochemical mesoscale tool for …

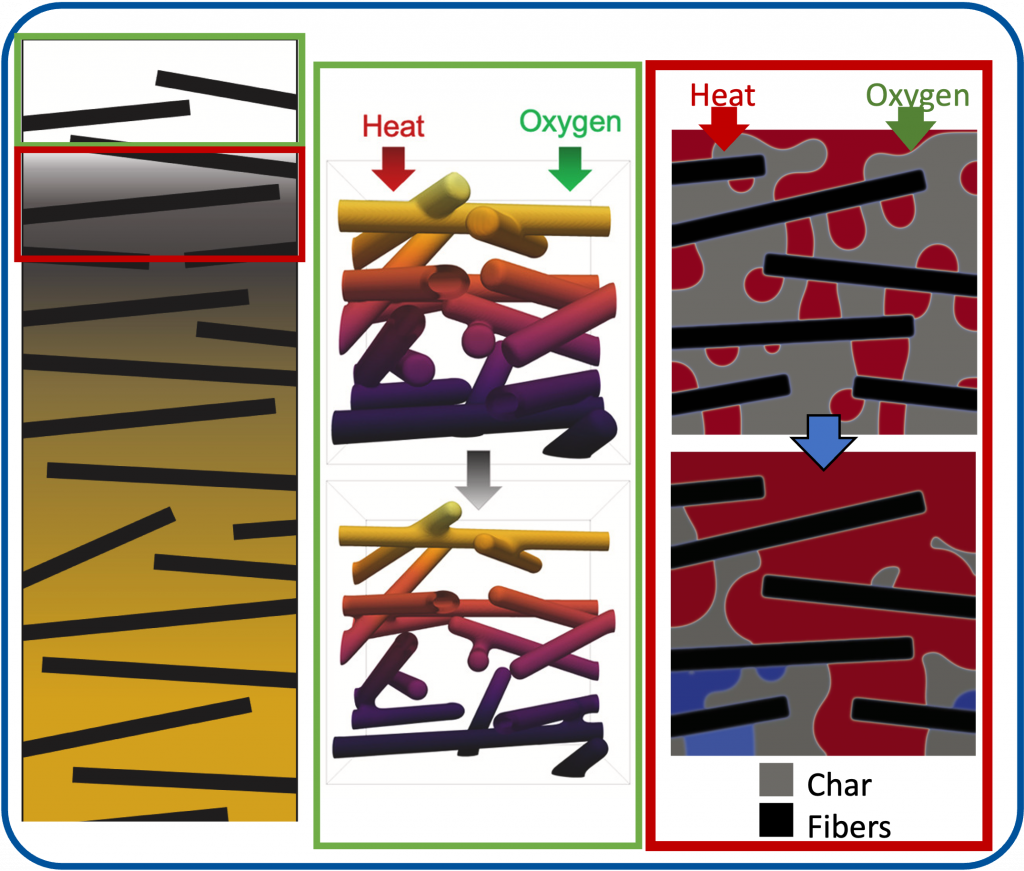

Modeling Carbon/Carbon composites for hypersonic applications

The objective of this work is to predict the ablation of Carbon-Carbon composite thermal protection systems (TPS) for hypersonic flight. We are accomplishing this by modifying the Macaw code that was originally developed for PICA TPS in past research (see below).

Researchers: Robert Clayton

Collaborators: Spectral Energies

Funding: Office of Naval Research

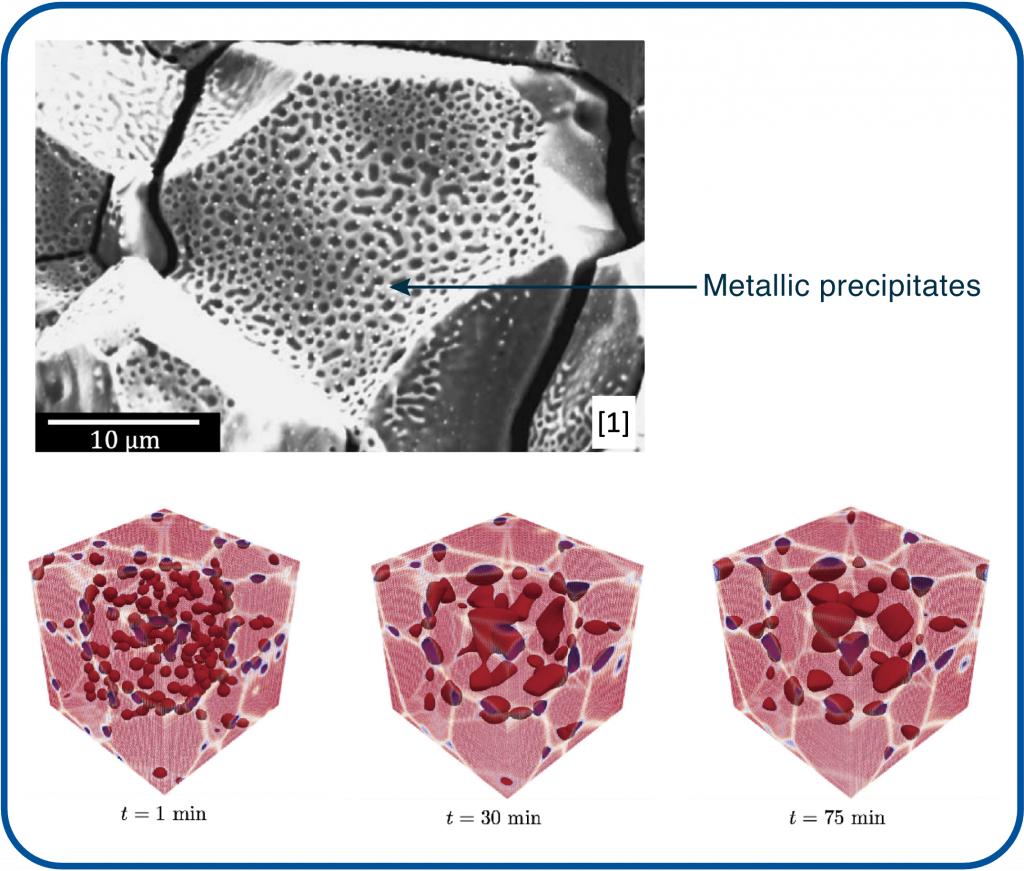

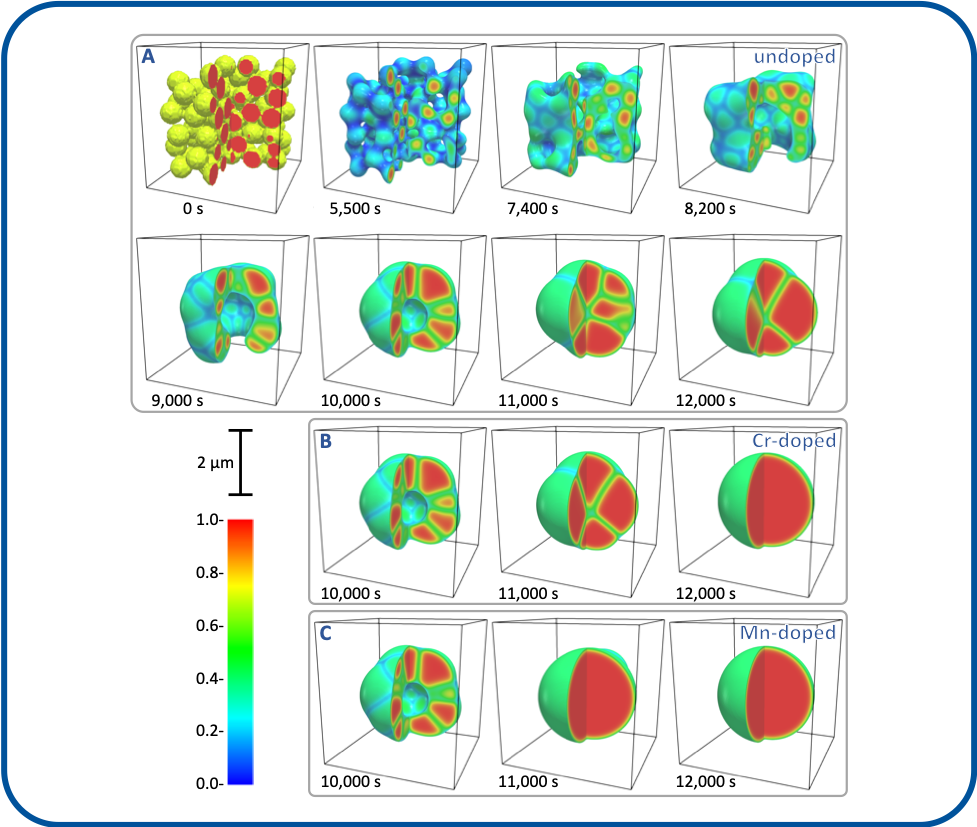

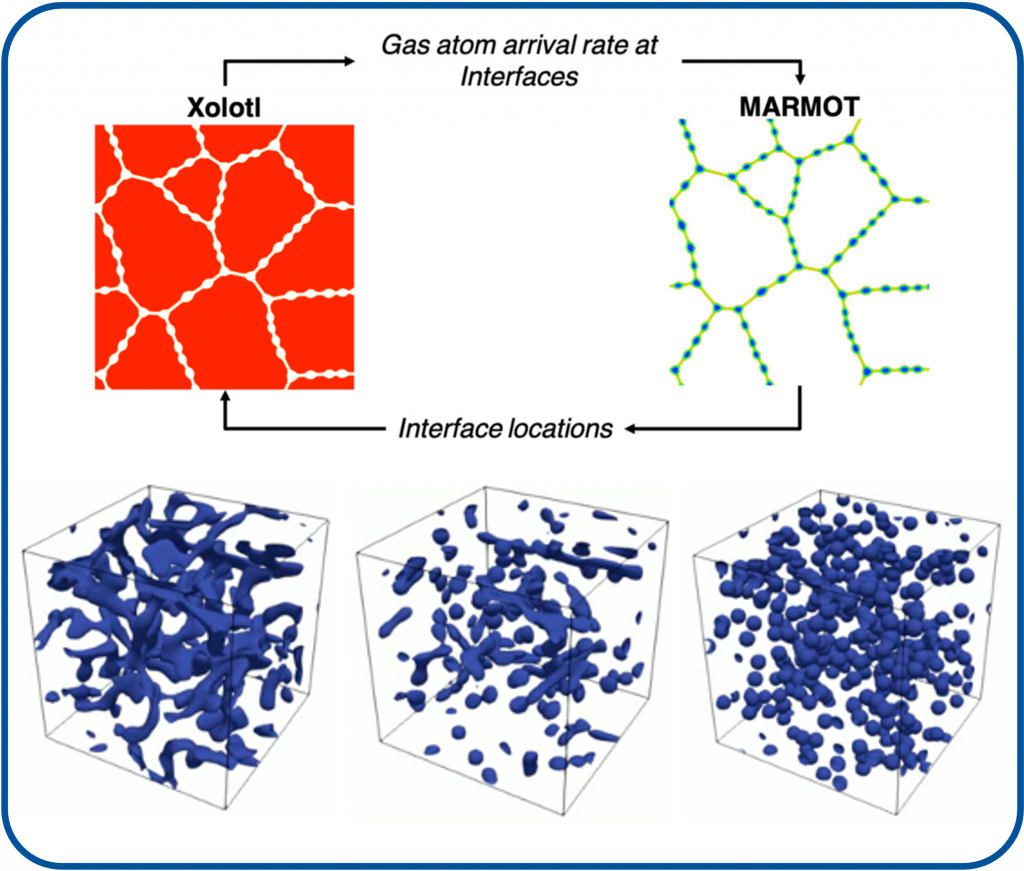

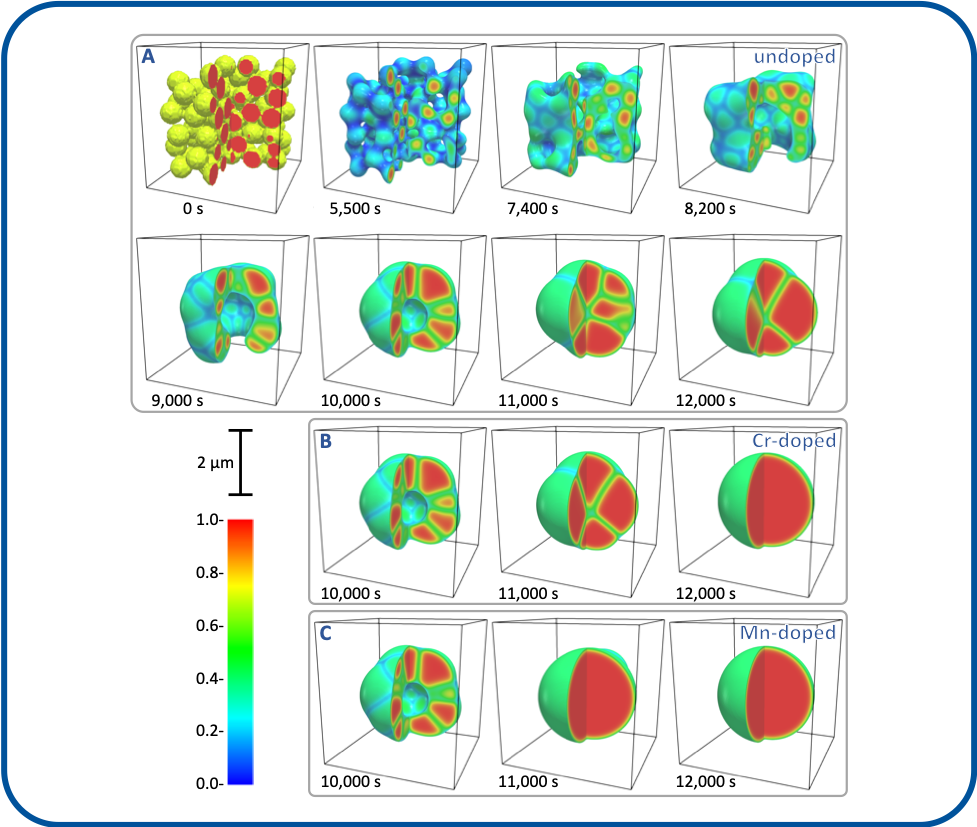

Studying the Interactions between Solid Fission Products and Fission Gas Bubbles in UO2 and Doped UO2

Fission gas release has a large impact on fuel performance. We are investigating the impact of fission product precipitates on fission gas bubble evolution and gas release in UO2 and doped UO2 fuel using the Xolotl cluster dynamics code coupled with the phase-field grain-growth model in MARMOT. References: [1] White, R. J. (2004). JNM, 325(1), 61-77.

Researchers: Tanvir Sakib

Collaborators: Michael Cooper and David Andersson from LANL

Funding: NEUP

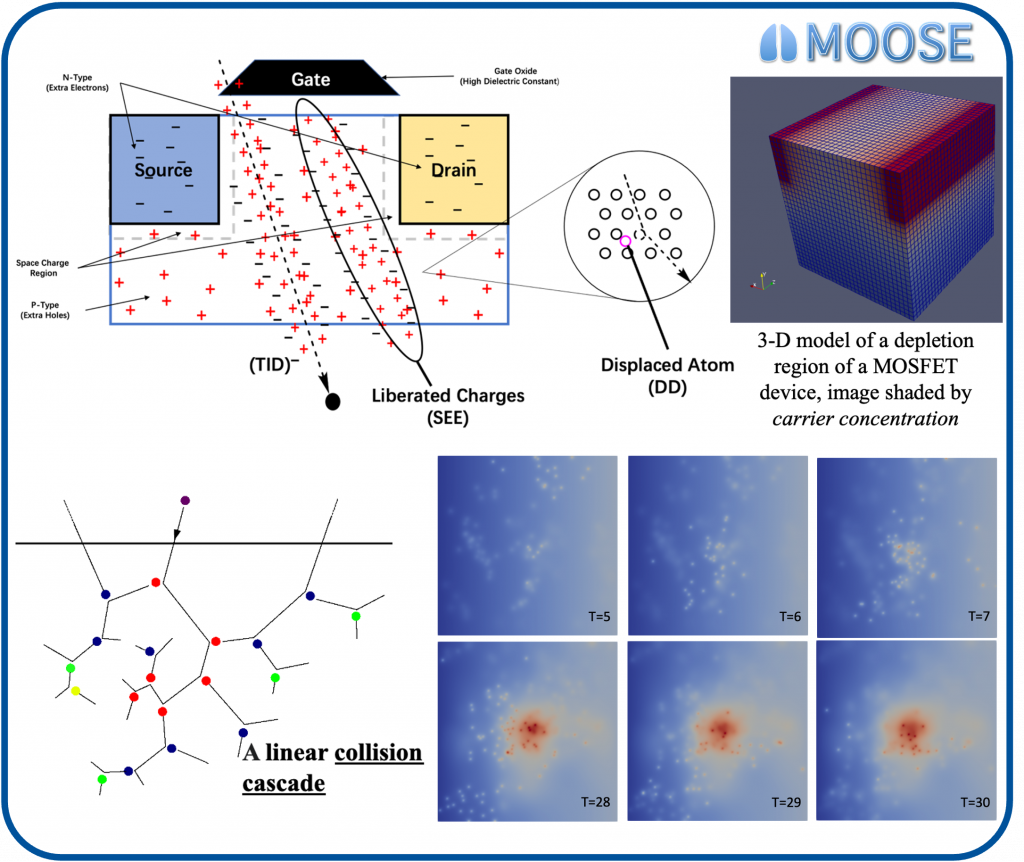

Impact of Ionizing Radiation on Semiconductor Devices

The performance of semiconductor devices degrades under ionizing radiation due to charged carrier injection and trapping, radiation damage, and heat generation. We are developing a multi-physics simulation capability that predicts the degradation of irradiated semiconductors.

Researchers: Xiaoyu Guan

Funding: DTRA IIRM

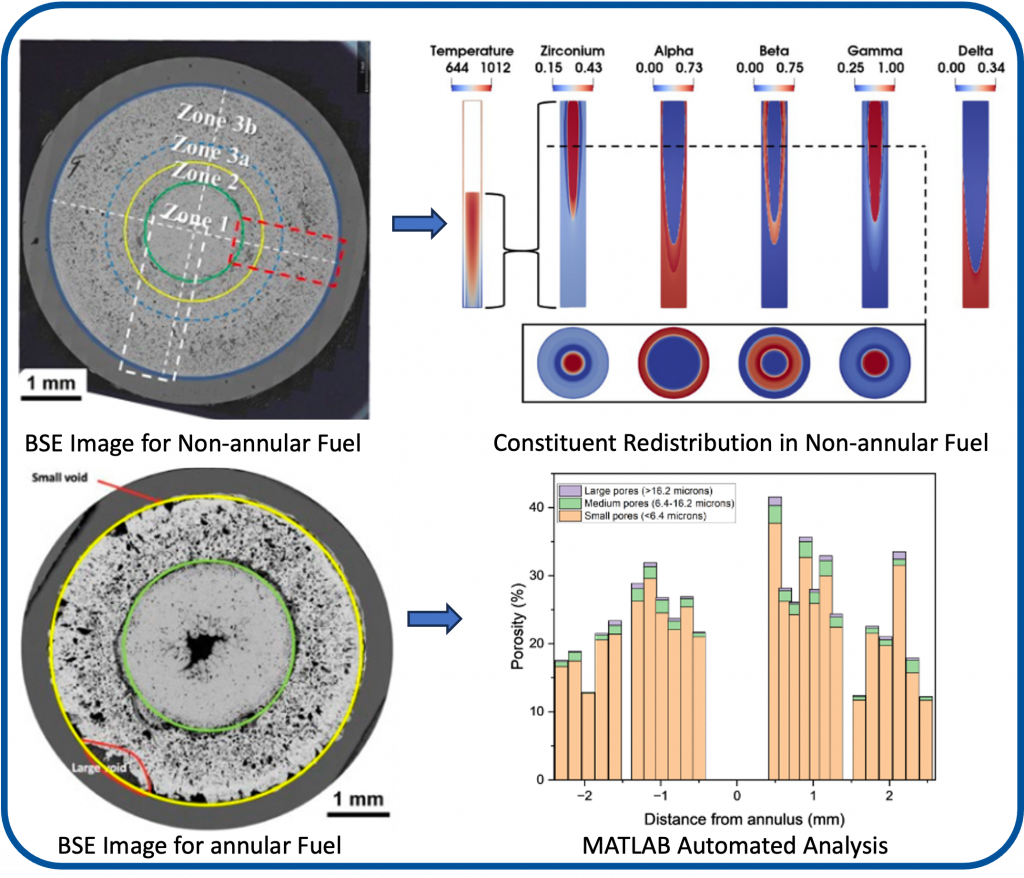

Understanding Constituent Redistribution, Thermal Transport, and Fission Gas Behavior in Annular U-Zr Metallic Fuel

We are investigating the cause of constituent redistribution in annular U-Zr fuel and how it impacts thermal conductivity and fission gas behavior. INL’s BISON fuel performance code and MARMOT will be used, both of which are based on MOOSE Framework. We will also compare these results with the experimental data provided by INL to develop and validate these models for annular fuel geometry.

Researchers: Yogesh Kumar

Collaborators: Assel Aitkaliyeva

Funding: NEUP 23-29552

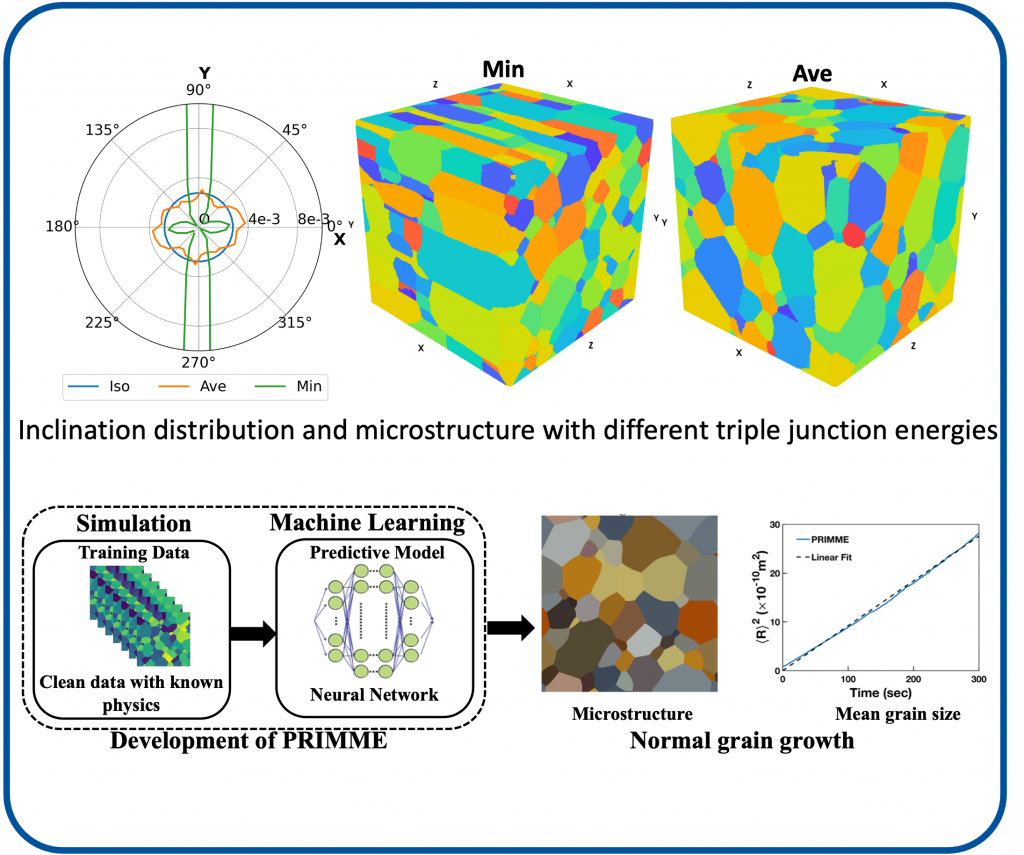

Understanding Abnormal Grain Growth

We are investigating the causes for abnormal grain growth using a combination of grain growth simulation, 3D microstructure characterization, and machine learning. We are developing grain growth simulations that consider the impact of grain boundary misorientation and inclination. The simulation results and experimental data are being used to train machine learning models that will teach us to understand grain growth.

Researchers: Lin Yang and Vishal Yadav

Collaborators: Amanda Krause (CMU), Joel Harley (UF), Michael Kesler (ORNL)

Funding: DOE BES

Papers:

A New Efficient Grain Growth Model …

Calculating the grain boundary …

A novel physics-regularized …

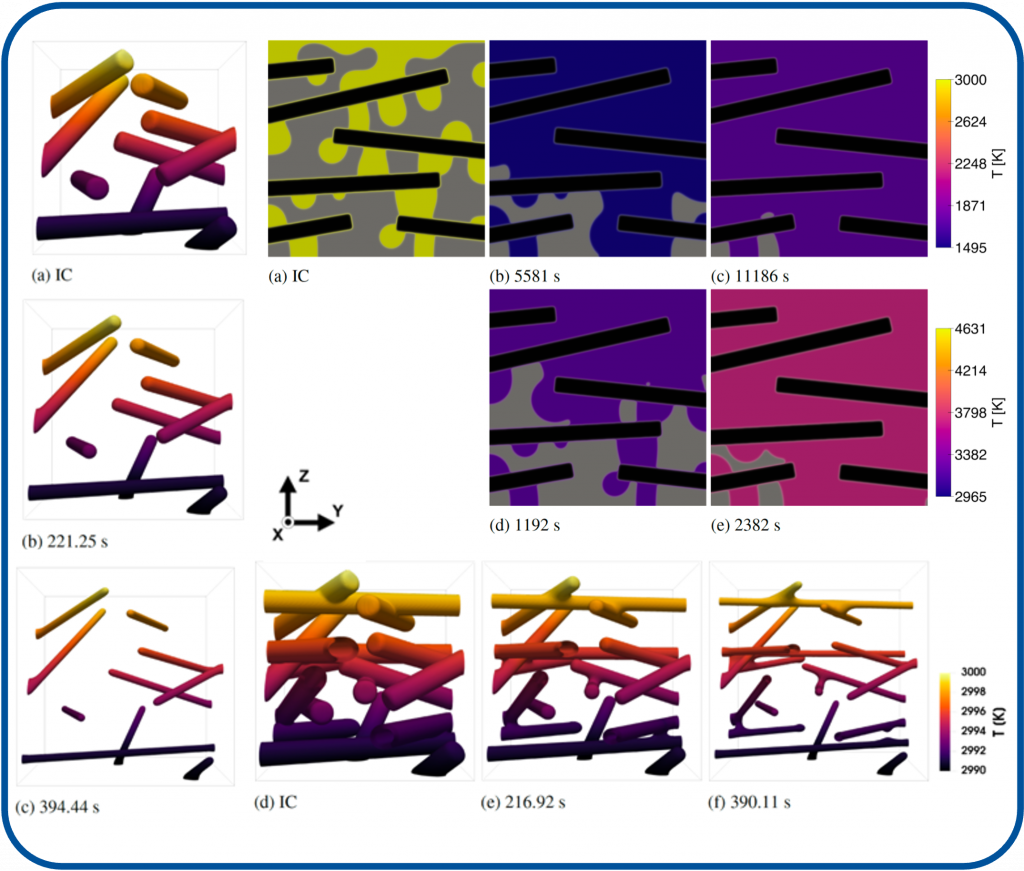

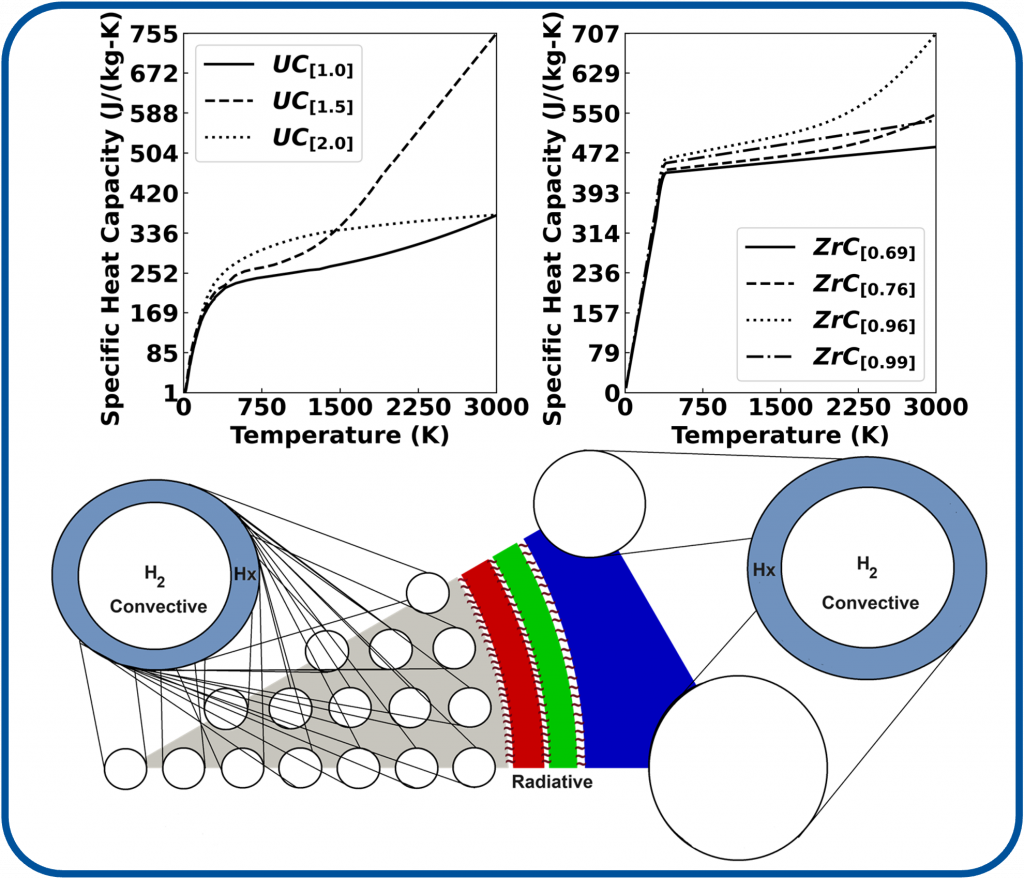

Nuclear Thermal Propulsion Advanced Carbide Fuel Performance

Nuclear thermal propulsion (NTP) is being pursued for space exploration. We are developing the capability to predict the performance of uranium, zirconium, niobium, and tantalum carbide fuel using Idaho National Laboratory’s MOOSE-based codes.

Researchers: Jeremy Smith and Vishal Yadav

Funding: NASA MSFC

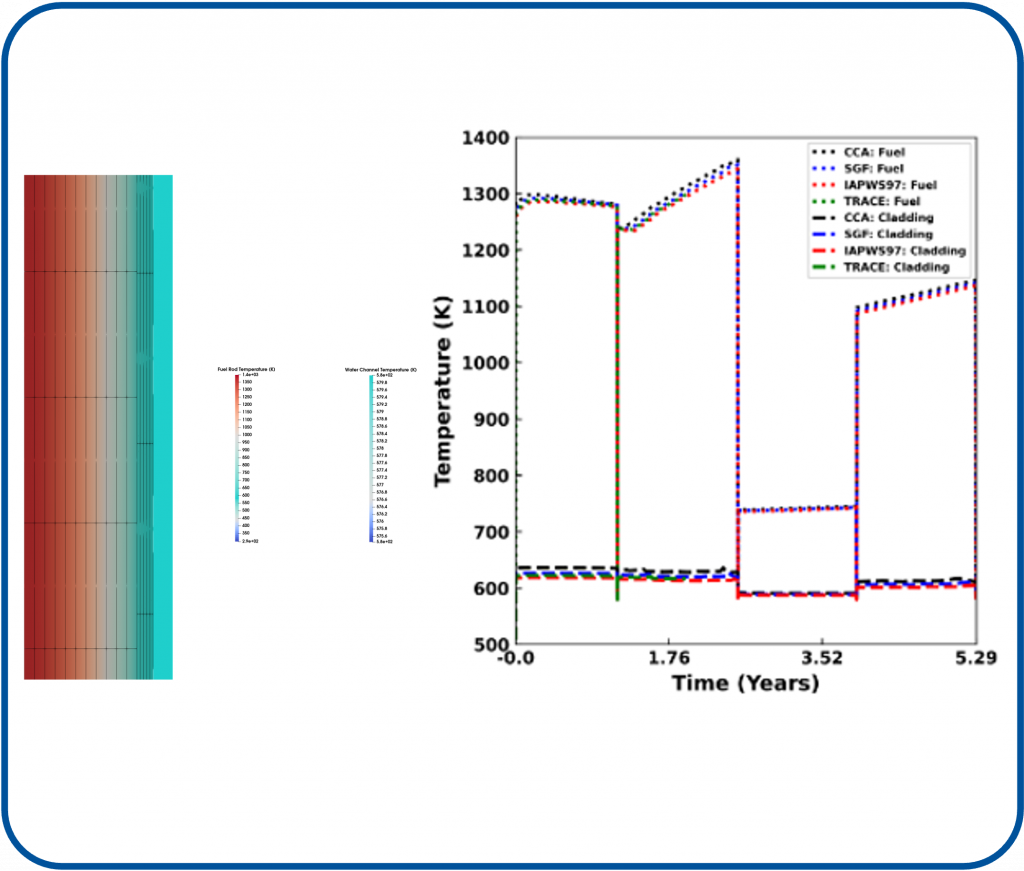

Multiphysics Modeling of High Burnup, Light Water Reactor Fuel During Loss of Coolant Accidents

We are augmenting the modeling capability for high burnup (> 55 GWd/MTHM) loss of coolant accidents in INL’s fuel performance code Bison with multiphysics coupling using the MOOSE thermal hydraulics module and the nuclear regulatory commission’s thermal hydraulics code TRACE.

Researchers: Jeremy D. Smith

Collaborators: Justin Watson

Funding: NEUP

Impact of Defects on Sintering and Densification in UO2

We are using modeling and simulation to better understand sintering and densification in UO2. We are considering the impact of stoichiometry on sintering and developing a mechanistic model if radiation enhanced densification.

Researchers: Brandon Battas

Funding: NEAMS

Past Research

These projects have stopped due to lack of funding, but they could be continued if there were interest.

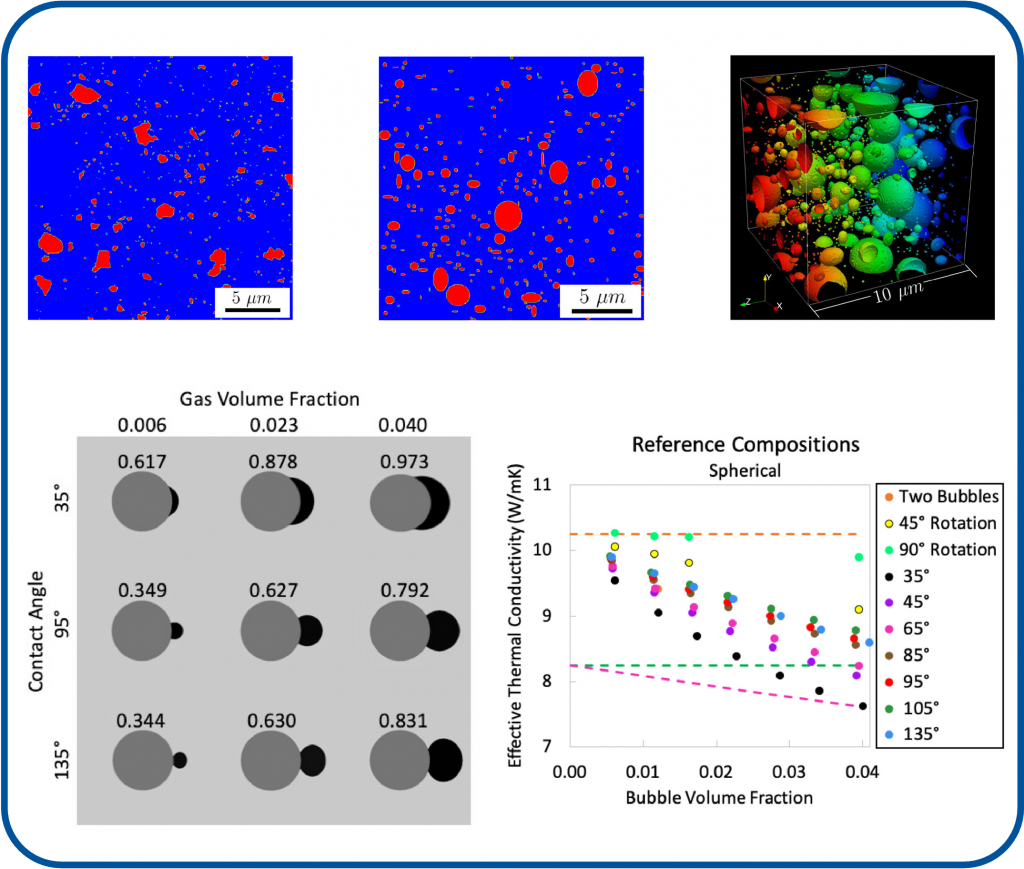

Modeling Fission Gas Bubble Evolution with Coupled Phase Field and Cluster Dynamics

To get a better understanding of fission gas bubble evolution in UO2, we have developed a hybrid model that couples a phase field model in MARMOT with a cluster dynamics model in Xolotl. We are applying it understand fission gas behavior on grain faces and edges.

Researchers: Ali Muntaha, Sourav Chatterjee, Dong-Uk Kim

Collaborators: Sophie Blondel and Brian Wirth from UTK, David Andersson from LANL, Phil Roth and David Bernholdt from ORNL

Funding: Joint NE/SciDAC

Papers:

Modeling mesoscale fission gas …

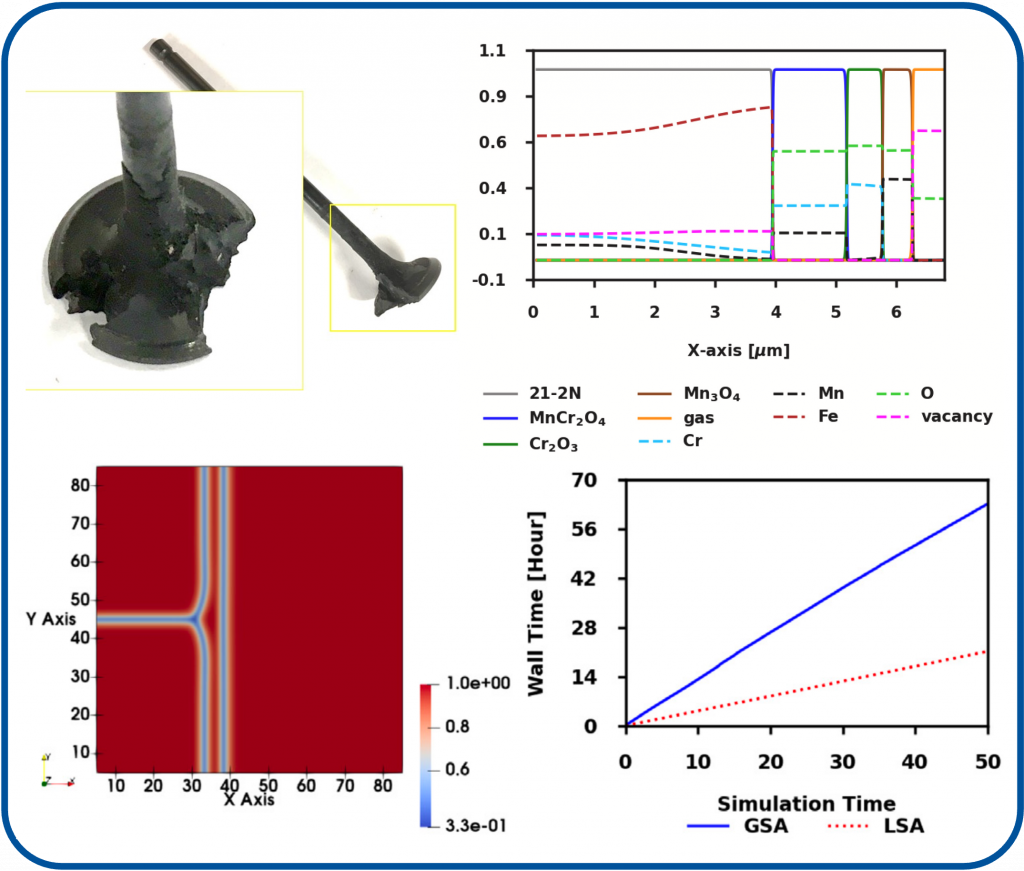

Oxidation of Valve Stainless Steels

We developed a phase field model of the oxidation of valve steels in a gasoline combustion environment. We also developed new capabilities to make KKS phase field models more efficient in the MOOSE framework.

Researchers: Xueyang Bognarova

Funding: DOE EERE

Papers:

A comparative study of two numerical …

A phase-field study of stainless-steel …

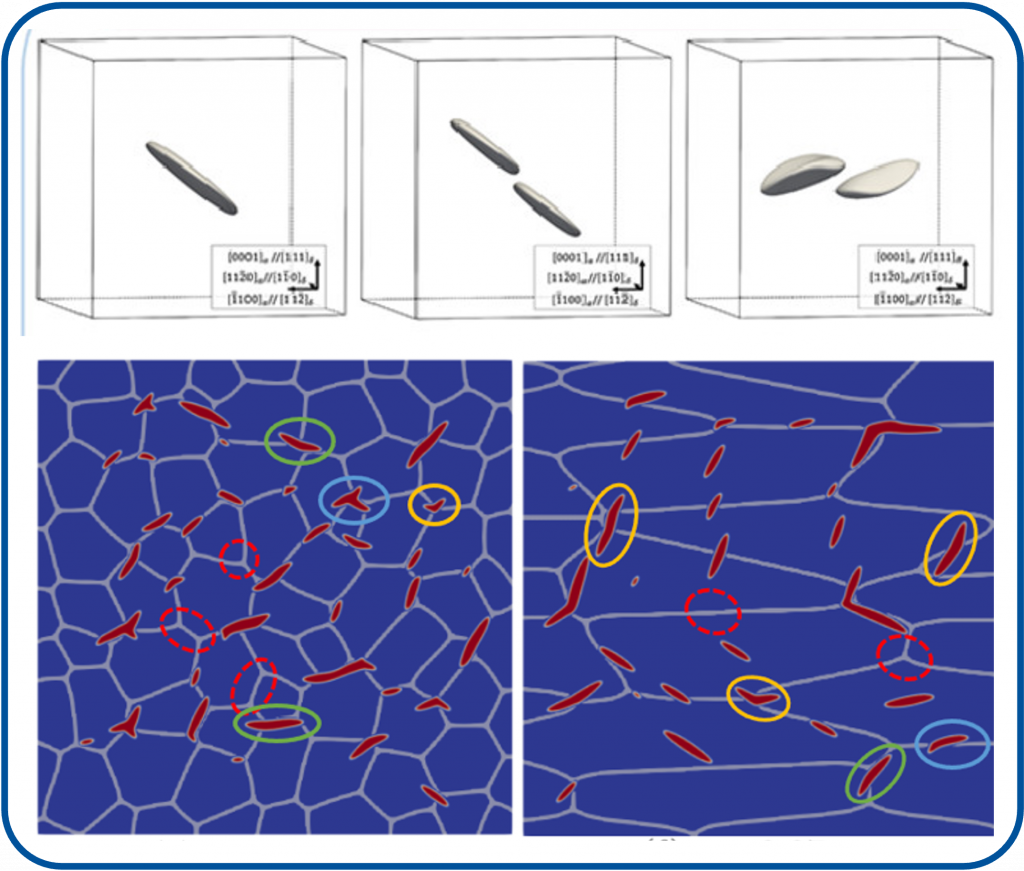

Hydride formation and reorientation in zirconium

We are investigating the mechanisms behind hydride formation in zircaloy cladding tubes. We have developed phase field models that predict the formation of individual hydride particles and different orientations of extend hydride structures, and approaches for quantifying the impact hydride microstructures.

Researchers: Pierre-Clement Simon

Funding: IRP

Papers:

Mechanisms of Mesoscale Hydride …

Investigation of δ zirconium hydride …

Quantifying the effect of hydride …

Carbon Oxidation in Ablative Thermal Protection Systems

We have developed models of the different zones that occur during the ablation of the Phenolic Impregnated Carbon Ablator (PICA) material that include fiber and char oxidation coupled with heat transport.

Researchers: Marina Sessim

Funding: NASA ESI Grant

Papers:

Phase-field model of char oxidation …

Phase-field modeling of carbon fiber …

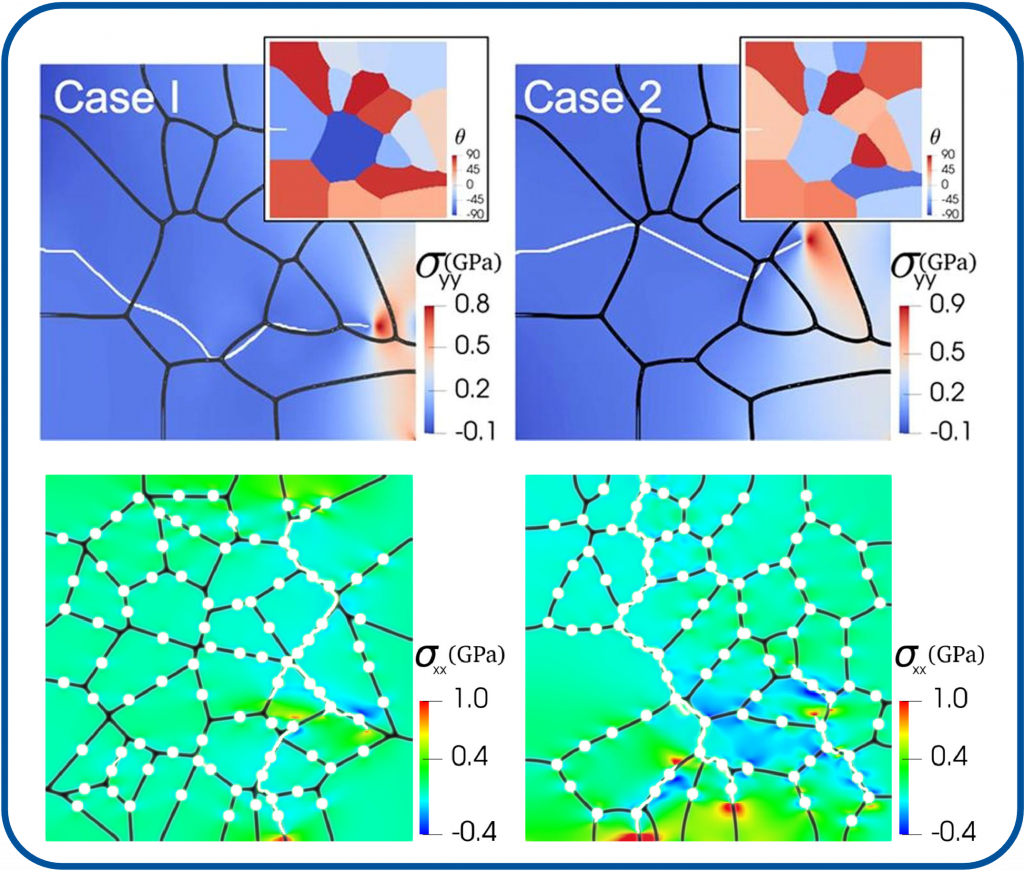

Simulations of microcrack behavior using phase field fracture

We are developing phase field fracture models to predict the nucleation and propagation of microcracks through brittle polycrystalline materials. We also apply the models to investigate the behaviors of materials in harsh environments.

Researchers: Shuaifang Zhang

Funding: NEUP, EPRI

Papers:

Comparing the impact of thermal …

Assessment of four strain energy …

A phase field model of crack …

A new phase field fracture model for …

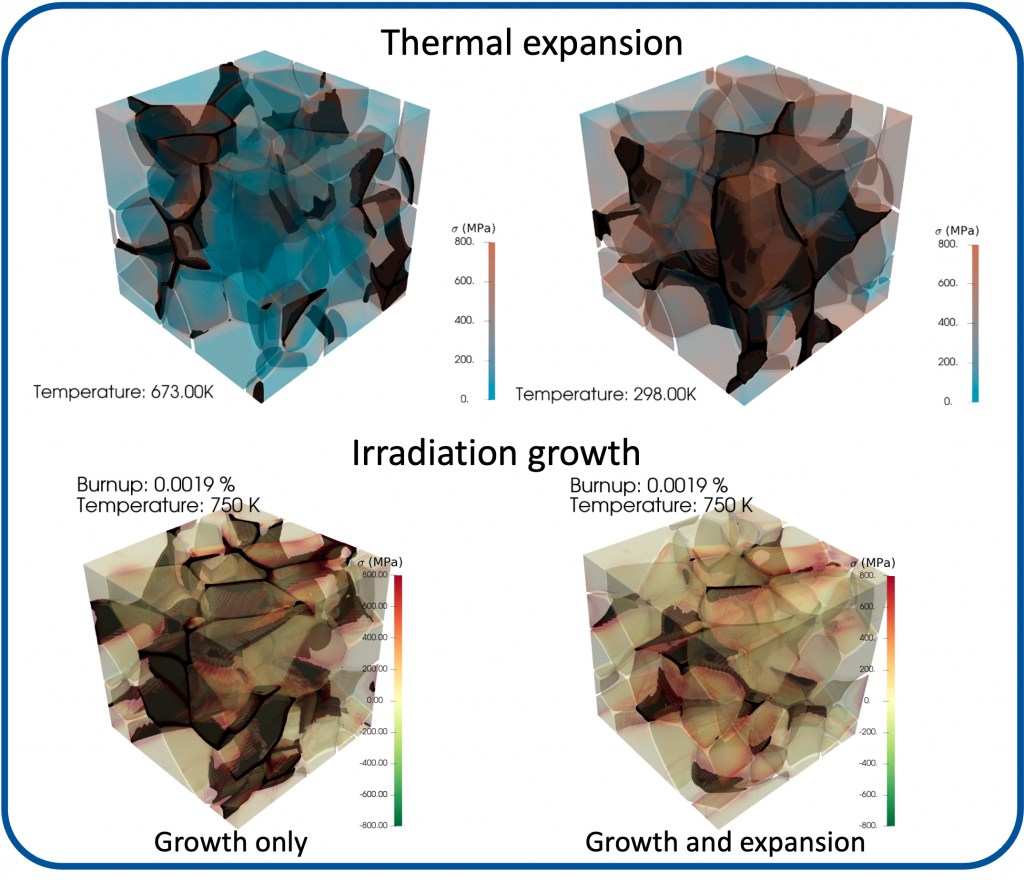

Fracture in Alpha Uranium due to Anisotropic Mechanical Behavior

We developed models of fracture in alpha uranium due to anisotropic mechanical behavior, including anisotropic thermal expansion during temperature changes and anisotropic growth during reactor operation.

Researchers: Aashique Rezwan

Funding: INL

Papers:

Modeling brittle fracture due to …

Performance of Composite Accident Tolerant Fuel

We are determining the properties of composite accident tolerant fuels, such as UO2 with high thermal conductivity additives. We also determine how the properties change due to microstructure evolution during reactor operation.

Researchers: Floyd Hilty

Funding: NEUP

Papers:

Impact of fission gas bubbles …

Development and application of …

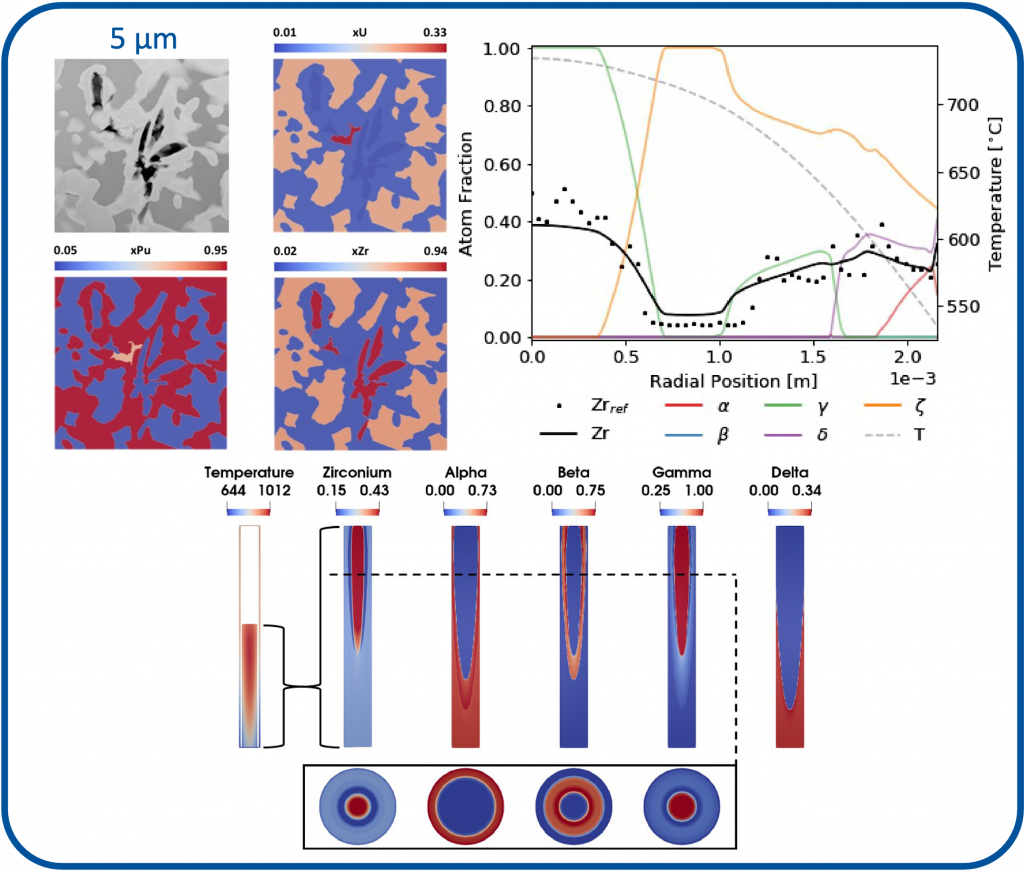

Phase Change and Constituent Redistribution in Metallic Fuel

We developed mesoscale and macroscale models of phase change and constituent redistribution in metallic fuel, including U-Zr and U-Pu-Zr. We also applied the models to help interpret experimental results.

Researchers: Jacob Hirschhorn

Funding: NEAMS and AFC

Papers:

A CALPHAD-informed approach to …

Reexamination of a U-Zr diffusion …

In search of θ-(Pu,Zr) in binary Pu–Zr: …

A study of constituent redistribution in …

The microstructure and thermodynamic …

Development and verification of a …

Grand Potential Sintering and Densification Model

We developed a graph potential phase field model of sintering and applied it to model sintering and densification of UO2.

Researchers: Ian Greenquist

Funding: NEAMS

Papers:

Development of a microstructural grand …

Grand potential sintering simulations …

Analysis of the impact of fuel …

Review of sintering and densification …